A gate valve, also known as a sluice valve, is a valve that opens by lifting a round or rectangular gate/wedge out of the path of the fluid. The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restric¬tion is desired. The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn’t be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry. On opening the gate valve, the flow path is enlarged in a highly nonlinear manner with respect to percent of opening. This means that flow rate does not change evenly with stem travel. Also, a partially open gate disk tends to vibrate from the fluid flow. Most of the flow change occurs near shutoff with a relatively high fluid velocity causing disk and seat wear and eventual leakage if used to regulate flow. Typical gate valves are designed to be fully opened or closed.When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low friction loss.

Gate valves are characterized as having either a rising or a no rising stem. Rising stems provide a visual indication of valve position because the stem is attached to the gate such that the gate and stem rise and lower together as the valve is operated. No rising stem valves may have a pointer threaded onto the upper end of the stem to indicate valve position, since the gate travels up or down the stem on the threads without raising or lowering the stem. No rising stems are used underground or where vertical space is limited.

Bonnets provide leak proof closure for the valve body. Gate valves may have a screw-in, union, or bolted bonnet. Screw-in bonnet is the simplest, offering a durable, pressure-tight seal. Union bonnet is suitable for applications requiring frequent inspection and cleaning. It also gives the body added strength. Bolted bonnet is used for larger valves and higher pressure applications.

Another type of bonnet construction in a gate valve is pressure seal bonnet. This construction is adopted for valves for high pressure service, typically in excess of 15 M Pa (2250 psi). The unique feature about the pressure seal bonnet is that the body – bonnet joints seals improves as the internal pressure in the valve increases, compared to other constructions where the increase in internal pressure tends to create leaks in the body-bonnet joint.

Gate valves may have flanged ends which are drilled according to pipeline compatible flange dimensional standards. Gate valves are typically constructed from cast iron, ductile iron, brass, cast carbon steel, gun metal, stainless steel, alloy steels, and forged steels.

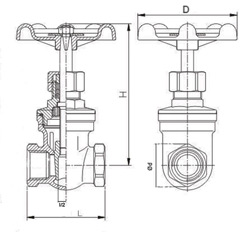

SIZE | Ø d | L | D | I | PT / NPT | H |

1/2 | 15 | 41.5 | 55 | 10.8 | 1/2 | 81 |

3/4 | 20 | 47.3 | 55 | 13 | 3/4 | 87 |

1 | 25 | 52.5 | 60 | 14 | 1 | 109 |

1 1/4 | 32 | 62.5 | 70 | 16 | 1 1/4 | 120 |

1 1/2 | 40 | 64 | 80 | 16.5 | 1 1/2 | 130 |

2 | 50 | 71.5 | 90 | 18.8 | 2 | 157 |

SKIZZ gate valve

Model : G.V – G.H

Connection Type : PT Thread / NPT Thread

Material : Brass

Working Pressure : 5kg / cm2 (ks) / 125PSI

Application : Water , Oil